In today’s increasingly busy logistics industry, ensuring the safe transportation of items of various shapes and sizes has become an urgent issue. The emergence of polyurethane materials provides us with a new solution — it can quickly foam according to the shape of the item to be packaged, providing excellent fixation, shock absorption, and cushioning.

Polyurethane material is a high-molecular compound with excellent physical properties and chemical stability. In the packaging field, one of its greatest characteristics is its ability to rapidly foam and perfectly shape. When polyurethane material encounters moisture in the air, it quickly undergoes a chemical reaction, releasing a large number of tiny bubbles, thereby achieving rapid foaming. These bubbles are closely arranged, forming a strong and elastic foam body that can tightly conform to the shape of the item, providing excellent fixation.

The advantages of rapid foaming and perfect shaping exhibited by polyurethane materials in packaging mainly manifest in the following aspects:

Firstly, polyurethane materials possess unique rapid foaming characteristics. When polyurethane material encounters moisture in the air, it quickly undergoes a chemical reaction, releasing a large amount of gas, forming a dense foam structure. This characteristic allows polyurethane material to quickly adapt and fill according to the shape of the packaged item. Whether it’s a complex curve or an irregular shape, it can perfectly fit in a short time, forming a tight and stable packaging structure.

Secondly, the perfect shaping ability of polyurethane materials is also a major advantage in packaging. By precisely controlling the foaming process, polyurethane materials can accurately replicate the shape of the packaged item, achieving customized packaging effects. This shaping ability not only enhances the tightness and stability of the packaging but also effectively reduces the gap between the packaging material and the item, thereby further enhancing the shock absorption and cushioning performance of the packaging.

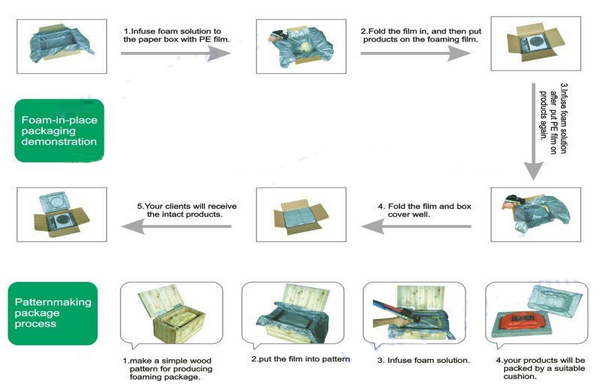

Additionally, the rapid foaming and perfect shaping characteristics of polyurethane materials also make the packaging process more efficient and convenient. Traditional packaging methods often require manual adjustments or custom molds based on the shape of the item, while polyurethane materials can automatically adapt to the shape of the item, greatly simplifying the packaging process and improving production efficiency.

In practical applications, these advantages of polyurethane materials are fully demonstrated. For example, in the packaging of precision instruments and fragile items, polyurethane materials can quickly foam and perfectly conform to the shape of the item, forming an effective fixation and cushioning layer, protecting the item from external impacts and vibrations. At the same time, in the packaging of complex-shaped items, polyurethane materials can also handle with ease, achieving comprehensive coverage and protection.

In summary, the rapid foaming and perfect shaping advantages exhibited by polyurethane materials in packaging make it an efficient, convenient, and reliable packaging material. These advantages not only improve the quality and efficiency of packaging but also provide better protection and safety for the packaged items.

Today, more and more companies and individuals are choosing to use polyurethane materials for item packaging. Whether it’s high-end precision instruments, fragile ceramics, or everyday items, perfect protection can be achieved through polyurethane material packaging. This customized packaging method not only improves the safety of items but also reduces the loss rate during transportation, bringing tangible economic benefits to businesses and individuals.

In conclusion, with its characteristics of rapid foaming and perfect shaping, polyurethane materials demonstrate enormous potential in the packaging field. It can provide customized packaging according to the shape of the item to be packaged and play a significant role in fixation, shock absorption, and cushioning. It is believed that in the near future, polyurethane materials will play an even more important role in the packaging industry, bringing more convenience and safety to our lives.